The Cosgrove Hall Films Archive is a small animation archive operating out of Waterside Art in

Sale, Manchester in the borough of Trafford. We are custodians of the animation archive and look after

all the physical assets leftover from Cosgrove Hall Films / Productions. Cosgrove Hall Films produced

model animation and hand-drawn animation, so our collection comprises stop motion models, moulds,

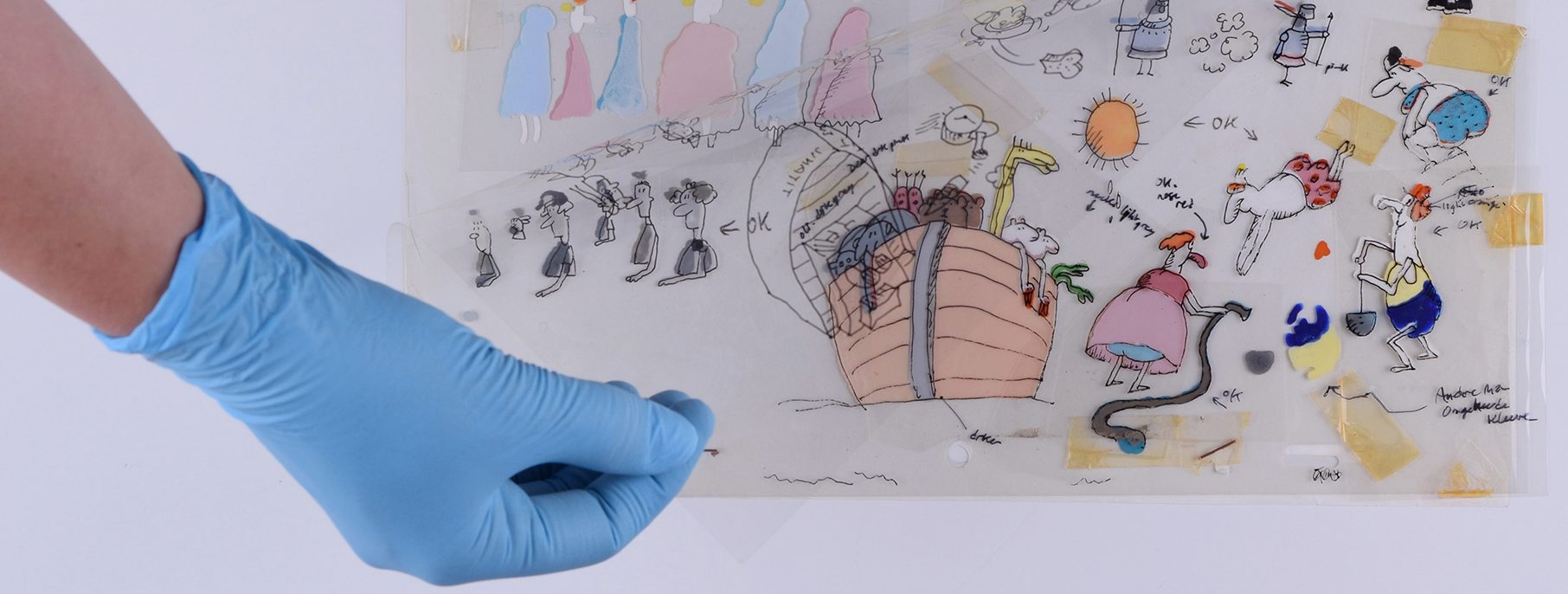

props and also a range of hand-drawn character designs, storyboards and drawings. We also have a

selection of production material created during the plan, shoot and editing phases of production.

Ahead of Materials in Motion 2021, we would like to share some information about the introduction of

foam latex and composite materials to Cosgrove Hall Films in the early 1980s. We are dealing with a

variety of materials from paper to plastics in our collection. Some of the most vulnerable areas of our

collection are on the model side. By looking at the progression of techniques used within the collection

chronologically, it is evident that model-making advanced over time at Cosgrove Hall.

The Introduction of Foam Latex at Cosgrove Hall

Cosgrove Hall Films did not rely on any single model-making technique to create animated

series, each series or animated film had a very distinct look and responded to each character design. We

have several examples of the use of everyday household materials throughout the 1970s. In early

productions such as Chorlton and the Wheelies (1976), car filler has been used to carve pre-sculpted

expressions. From the condition of these, we can tell car filler is a robust material. Although these

expressions were moulded and painted in the 1970s they are in excellent condition today in comparison

with later foam latex models. Throughout the 1970s, carved rubber foam and balsa wood seemed to be

other favoured materials. Noticeable ageing effects on rubber foam are that it discolours, but it still

maintains its compressible quality. Materials such as these are lower risk within the archive when

compared with materials used in model-making throughout the 1980s.

In the early 1980s, we start to see the introduction of more composite materials in model-making, in

1981 model-makers at Cosgrove Hall used Chemiwood high-density polyurethane foam when sculpting the characters for Cinderella

(1981) to achieve a smoother, more defined finish to the sculpts. The majority of models Cosgrove Hall

made from the mid-1980s onwards tend to be made from foam latex and later, silicone and epoxy resin.

In the early 1980s, Cosgrove Hall model-maker Peter Saunders worked on a bigger budget

feature film and learned about techniques used in special effects and prosthetics, particularly the use of

foam latex. Peter introduced foam latex into model-making at Cosgrove Hall, just on a much smaller

scale. The Wind in the Willows film (1983) was the first Cosgrove Hall production to use this material.

These models were constructed with an engineered internal skeleton, with a hinged ball and socket

construction. Over the top of these, a moulded foam latex skin would sit. The lightweight skin could

easily be stretched over the top of the armature like a jumper. A combination of an engineered armature

with a foam latex skin over the top also allowed animators to create a fluid lip-syncing detail and refined

movement.

Within our collection, we also have models with a complex internal armature made with silicone skins

instead of foam latex, such as Engie Benjy (2002). Silicone has also been favoured in later productions on

elements such as hands and feet of the models, possibly because it seems to clean better and animators

would be manipulating these elements heavily on set. Andy Pandy (2002) relies on pre-sculpted

interchangeable heads made from epoxy resin and yet the series use silicone for hands and feet. This

indicates model-makers responded faithfully to character design by evaluating the requirements. Andy

Pandy did not require lip-syncing and so using pre-sculpted interchangeable heads with silicone

elements was sometimes preferable to foam latex, however, characters such as Teddy Bear from the

same series were made with foam latex as his skin is highly textured.

Andy Pandy

Therefore, beyond 1983, the use of foam latex at Cosgrove Hall seems to be used in a context where

there is a high level of detail needed within the character design, either embedded within the texture of

the skin or through the level of detail needed in the lip-syncing.

Observations of Foam Latex Degradation

Based on our observations up to this point, we believe it’s a crucial time to initiate a conservation

program within the archive. We’ve observed that foam latex in particular is very sensitive to degradation

and is the most degraded and fragile material within our archive. When the foam latex is first formed it is

lightweight, pale yellow in colour, with a soft flexible texture. As it degrades it becomes more brittle, it

begins to crack and crumble into a dusty powder. The material also off-gases and discolours, becoming

darker, more orange before it begins to decay and disintegrate.

There is visibly no consistency between the rate of deterioration and age of the puppets we are looking

after. For example, the foam latex puppets from the series Oakie Doke (1995) have several characters

which are in an excellent condition where you can still see all the details and textures in the surface of

the foam latex and the surface still has a spongy, soft texture, whereas we have other characters from

the same series where the foam latex has taken on a crumbly consistency and is very worn.

The differences in how puppets deteriorate may be due to varying solutions of the foam latex. Foam

latex is formed by combining liquid latex with a foaming agent, curing agent and gelling agent, this

mixture is then baked in an industrial oven. Depending on how much time the model has been baked for

or how much each of the agents has been applied its batch consistency will vary.

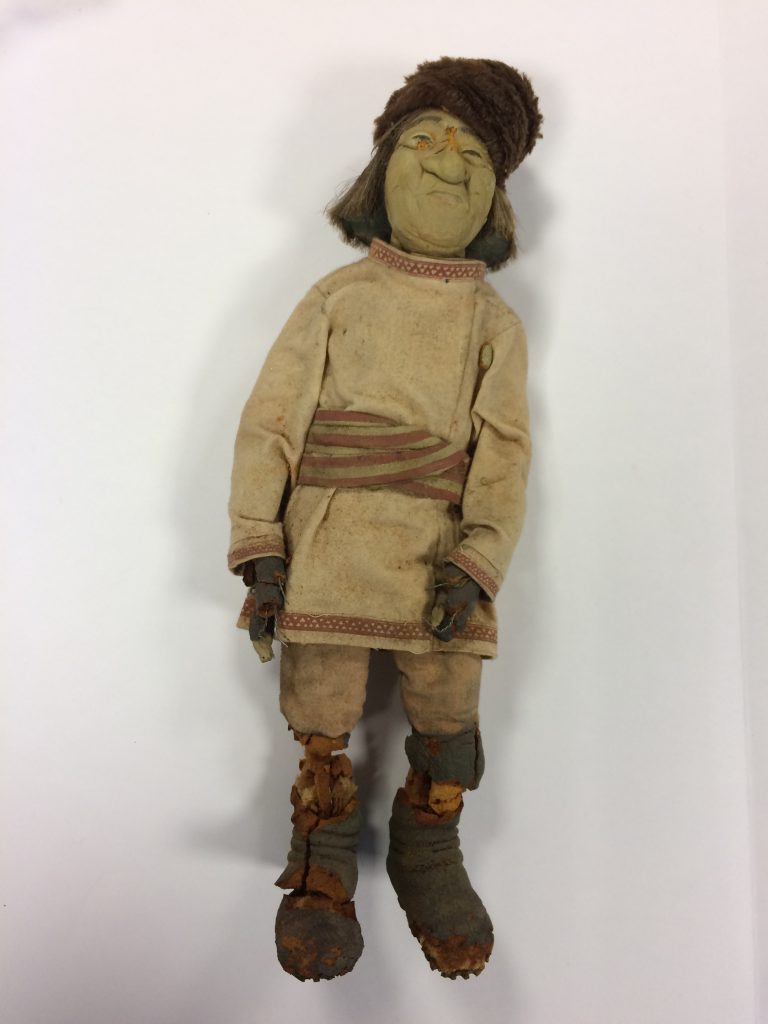

We’ve observed that foam latex models from particular shows seem more susceptible to crumble and

are at the most risk of deterioration. For instance, the models from Fool of the World and the Flying Ship

(1991), we’ve observed the majority of the puppets are discoloured and wearing away. One or two of

these puppets are in a better condition and could be due to how those particular puppets were stored. It

is also noticeable that the main characters, which would have been manipulated by hand by animators

during the making of the film are noticeably more degraded than secondary characters, suggesting that

residue on your hands stimulates their deterioration, and these assets will have been handled heavily

during the animation process.

Flying Ship (1991

This material will also be sensitive to a number of environmental factors which are likely to accelerate

the degradation process. The material will undoubtedly continue to degrade, even if we minimise

exposure to these. We have taken some precautionary measures in storage, such as storing the models

in a dark, cool space, and storing the models with an oxygen scavenger and acid-free materials which are

changed regularly. However, we expect that they will continue to degrade even with these measures in

place.

Why did animators continue to use foam latex if it degrades?

The weathering of foam latex meant very little to animators since their focus would have been on the

production at hand. Foam latex skins were easy to use on set as they were lightweight and allowed

animators to manipulate the compact ball and socket joints of the armature.

The material was highly versatile and often used within prosthetics and special effects in feature films

because of the level of realistic detail. Peter Saunders initially developed foam latex skins for the

puppets, which were highly detailed and beautifully intricate and have a delicate quality that comes

across on film. In truth, these materials were not made to last, however researching and minimising

exposure to these variables which stimulate degradation helps us to preserve the material for longer.

As a small archive without a conservator in-house, we have had to be really resourceful and factor

conservatorship into our future planning. This next phase in our archive centres around foam latex

conservation. Despite these limitations, we are aware of the fragility of the material, and learning about

the material has meant that we are able to adapt and orient our future plans so as to advocate for the

need for animation specific conservatorship.

Materials in Motion is an important platform for us to network with specialists with knowledge and

interest in animation specific materials such as this. Discussing what we know, we hope to stimulate a

valuable discussion and research in this area.

Further reading

www.cosgrovehallfilmsarchive.co.uk

Cosgrove. B, The Cosgrove Hall Story (2018), publisher not identified. Reference copies available at

Cosgrove Hall Films Archive and BFI’s Reuben Library.

Kula, D., Elodie Ternaux, Hirsinger, Q., Maroussia Jannelle, Gomez, B. and Matério (Firm (2014).

Materiology : the creatives guide to materials and technologies. Amsterdam: Frame Publishers ;

Basel.

POPART: Preservation of Plastic ARTefacts in museum collections

Purves, B. (2010). Basics animation. 04 : Stop-motion. Lausanne: Ava Academia ; La Vergne,

Tenn.

Spelling error report

The following text will be sent to our editors: